The Static Bar, or Ionizing Bar, is powered by 6000V or 7500V Power Supply for Maximum High Speed Static Elimination.

Model 55000 Series Static Bars feature a unique, inductively coupled design that produces powerful static neutralization, while remaining shockproof. As static control components, these ionizing bars are ideal for sheet, webs and shallow three-dimensional parts. Static bars can be positioned up to 6″ from the target.

Each static bar is supplied with 8′ of cable. When connected to the 50002 Power Unit, the stainless steel pins in the static bar, or ionizing bar emit an ionized corona which supplies ions of both polarities for static neutralization. When a statically charged item passes through the ionizing bar corona, the free moving ions are drawn to the opposite charge on the item. This is how these static control components neutralize the static. The body of the static bar is anodized aluminum, with stainless steel emitter pins in plastic molding. The inductively operated static bars feature a power light to indicate On/Off operation.

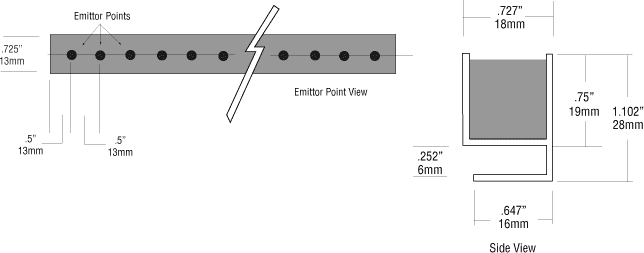

All Static Bars are available with effective length of 3″ (76 mm), 6″ (152 mm), 12″ (305 mm), 18″ (457 mm), 24″ (610 mm), 30″ (762 mm), 36″ (914 mm), 42″ (1067 mm), 48″ (1219 mm). Overall length is 1.5″ longer than effective length. Last 2-digits in the model numbers of the static bars model indicate the effective length. Sample: Model 55012 is 12″ effective length.

Static Bars

AiRTX Ionizing Bars Advantages

- Anodized Case

- Heavy-duty shielded power cable for long life and protection

- Quick connect plug-in to power supply

- Stainless Steel emitter points

- Shockless operation

- Static elimination 6″ from bar and 20′ from ionizing bar using the Airtx Air Knife

- 6000V of Power means 20% more ions than other suppliers

- Indicator light on Ionizing Bar to show power

- 7500V of Power means 35% more ions than other suppliers

INDUSTRIAL SOLUTIONS FOR STATIC BARS

- Pre-paint prep areas

- Sheet feeders, unwinders, stackers, separators

- Lenses, signs, etc.

- Packaging materials

- Pneumatic conveyors

- Injection molded parts

- Cutters and slitters for trim removal

- Heat-set ink dryers, paper and textile drying equipment

- Around guide rods and rollers on any machinery handling web or sheet paper and plastic

- Electronics assembly areas or servicing of boards and components

- Photofinishing operations

TECHNICAL DATA FOR IONIZING BARS

Ionizing Bars are powered by a high voltage Power Supply for Maximum High Speed Static Elimination. Ionizing bars incorporate a unique inductively coupled design, which achieves powerful static neutralization with complete shockproof operation:

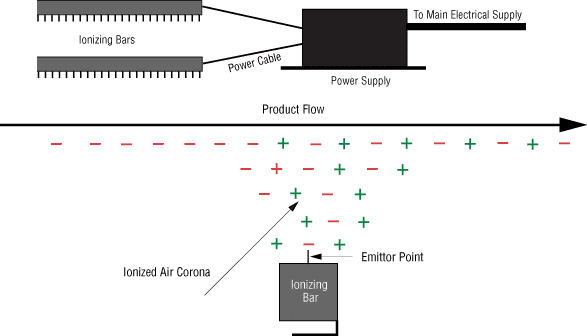

HOW IONIZING BARS WORK

The power supply converts the primary (115V or 230V) electricity supply into a high voltage low amperage output. This output energy is transferred to the ionizing bar through the power cable. A capacitive coupling inside the bar reduces the energy to a level which is completely shockproof to a human but creates a large potential of ions for neutralization.

The stainless steel pins in the bar emit this energy (Corona Discharge) in the form of a field of ionized air. This ionized air corona supplies ions of both polarities. Thus it is able to neutralize static charges of positive or negative. When a statically charged object or material passes through this corona, the free moving ions are attracted to the opposite charge on the material. In this way the static electricity is neutralized. The ions are emitted up to 6″ from the bar and have a life of approximately 2 seconds before they recombine with themselves or the atmosphere.

The typical AiRTX Static Elimination installation consists of one or more Ionizing Bars connected to an AiRTX Power Supply.

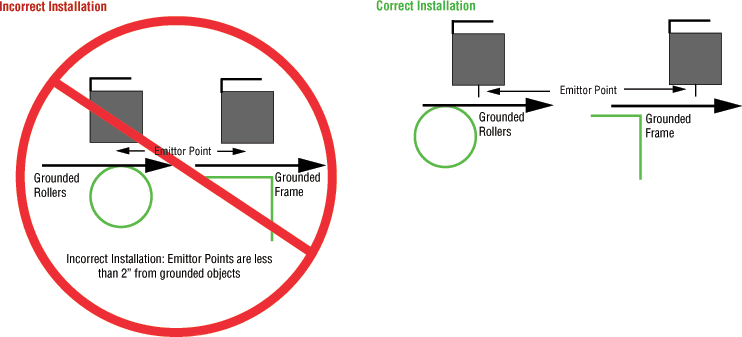

INSTALLING IONIZING BARS

Correct Positioning is Vital to the Efficient Operation of Static Elimination Bars. Factors to be considered are:

- Correct positioning relative to the problem, i.e., immediately before problem area, with no intermediary rollers or processes which could regenerate the charge.

- Speed of material – higher speeds require more static elimination.

- Conductivity and density of material. The less conductive or more dense (molecularly) the material, the more stubborn will be the charge.

- Grounding – vitally important to the correct operation of bars. They will not function and will become “live” if not properly grounded.

The Following Rules Should Be Observed When Installing AiRTX Ionizing Bars

- Optimal Distance from material to be neutralized is 2″ – 4″

- Bars should be staggered if positioned on opposite sides of the material—distance between bars should not be less than the distance of either bar to surface (2″ – 4″)

- Avoid proximity to grounded parts of the machine – Grounded objects will distort the corona and reduce its efficiency.

- CAUTION: This equipment is NOT to be used in hazardous vapor areas.