Efficient & Energy Saving for Drying, Cooling, or Cleaning

Air knives are the most efficient and energy saving method to deliver compressed air for large drying, cooling or cleaning applications. An air knife creates huge volumes of air with lower compressed air costs, by entraining surrounding air. Three models of air knives deliver air at 25:1 to 50 times the amount of compressed air used to help with your application needs.

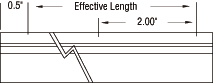

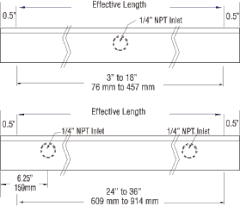

All air knives are available with effective length of 3″ (76 mm), 6″ (152 mm), 12″ (305 mm), 18″ (457 mm), 24″ (610 mm), 30″ (762 mm), 36″ (914 mm). Overall Length is 1″ longer than effective length to allow for air on either end. Custom sizes upon request.

Industrial Solutions For Air Knives

Printing and Binding

High speed binding requires quick drying of the glue so books can be fed along the stacking conveyor. The high volume of air from the model 85012 Air Knife speeds the outer drying of the glue so the conveyor can operate at maximum speed.

Textiles

The Model 86036 Hurricane Air Knives are ideal for cleaning and drying large rolls of cloth.

Painting

The 36″ Model 82036 Slim Line Air Knife with air filter creates an air barrier and helps prevent airborne powder from reaching the worker. The Slim Line construction ensures easy clean-up and long life.

Powder Coating and Curing

The model 85024 Aluminum Air Knives cool wheel rims as they exit powder coating ovens.

Advantages of an Air Knife

- 50:1 Air Flow Amplification (Series 86000 Air Knife)

- Wide area blow-off or cooling with less noise

- Replace open line jets with AiRTX Air Knives

- Low initial and operating costs

- Up to 70% less compressed air usage than open air line

- Easy to control flow/force

- No rotating machinery, guards or clumsy ducts

- No maintenance, no moving parts

- No electricity or explosion hazard

- No RF/EMI interference

- Instant on/ off

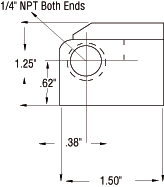

- Slimmer Cost – 20 to 25% Cost Savings over conventional Air Knives (Series 82000)

- Slimmer Air Usage – 30% less consumption with same (Series 82000) 25:1 Air Amplification (Series 85000/80000)

- Convenient Rear Connection to compressed air source (Series 82000)

- Quiet

Uses For AiRTX Air Knives

- Removing water from sheet plastic or metal

- Blowing off chips, trim scrap and swarf

- Parts cleaning before painting

- Creating an “air wall” between processes

- Cooling extruded parts

- Cleaning/cooling of metal strip and plastic/paperwebs

- Cleaning/cooling of conveyors and conveyorized parts

- The Slim profile provides a perfect solution in a tight working environment (Series 82000)

Technical Data For High Thrust Jets

All Air Knives Available with effective length of 3″ (76 mm), 6″ (152 mm), 12″ (305 mm), 18″ (457 mm), 24″ (610 mm), 30″ (762 mm), 36″ (914 mm). Overall Length is 1″ longer than effective length to allow for air on either end. Custom sizes Upon request.

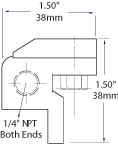

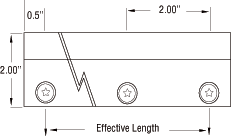

Aluminum Industrial Air Knife – Series 85000

End View Aluminum Air Knife”Entrained Air Versus Conventional Open Air Lines”(25:1 Air Amplification)

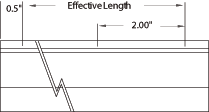

Stainless Steel Industrial Air Knife – Series 80000

End View Stainless Steel Air Knife

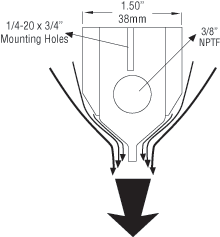

Aluminum Hurricane Air Knife – Series 86000

Entrained Air From Both Sides Versus Conventional One Sided Air Knives (50:1 Air Amplification)

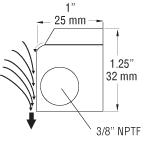

Aluminum Slim Line Air Knife – Series 82000

End View Slimline Air Knife Entrained Air Versus Conventional Open Air Lines (25:1 Air Amplification)

Part Number – Series 80000 Air Knives:

- 1st digit 8 represents Air Knives Series

- 2nd digit 5 is aluminum

- 2nd digit 0 is stainless steel

- 2nd digit 6 is aluminum Hurricane

- 2nd digit 2 is SlimLine

- 3rd digit 1 = with filter

- 3rd digit 2 = w/ Filter and regulator

- Last 2 digits is effective length

Air Knives

Overall length is 1″ longer than effective length to allow for air connection to either end.

Shims

Air Knives over 18″ should be supplied with air from both sides.

Increase air flow from the Air Knife by installing additional .003″ shims. Stainless Steel shims are available for high heat applications.

Custom sizes available.