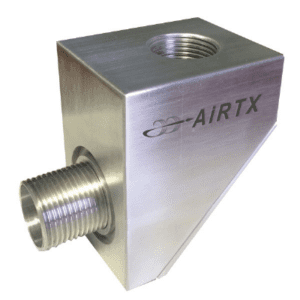

AiRTX Cabinet Coolers provide environmentally friendly, low cost cooling for electronic control panels in hot and hazardous conditions. They condition the air inside electrical enclosures, eliminating downtime due to heat, dirt and moisture. The AiRTX cabinet coolers incorporate a vortex tube to produce cold air from compressed air, without the use of moving parts.

-

Cabinet Coolers

Price range: $426.00 through $3,637.00 Select options This product has multiple variants. The options may be chosen on the product page -

Cabinet Cooling Enclosure

Price range: $1,378.00 through $1,478.00 Select options This product has multiple variants. The options may be chosen on the product page -

Cabinet Cooler Ducting Kit

$42.00 Add to cart -

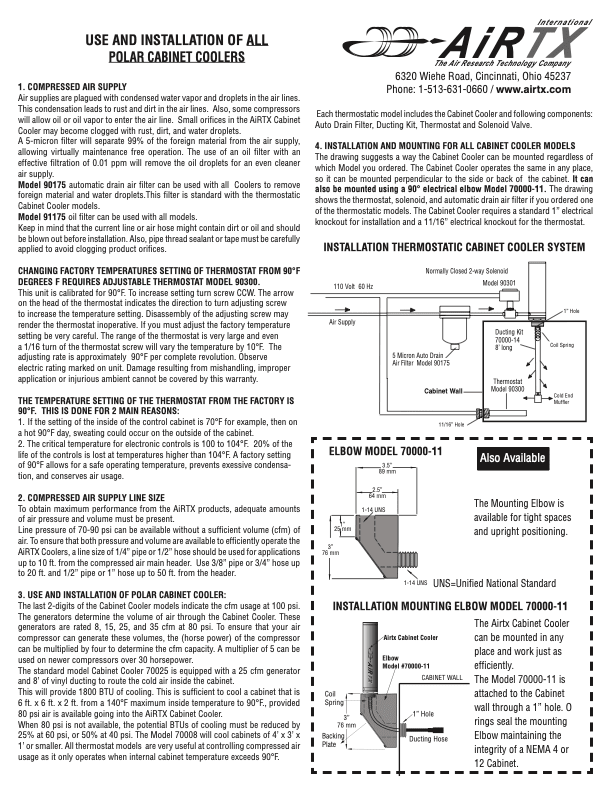

90° Cabinet Cooler Mount

Price range: $126.00 through $594.00 Select options This product has multiple variants. The options may be chosen on the product page

Industrial Solutions For Cabinet Coolers

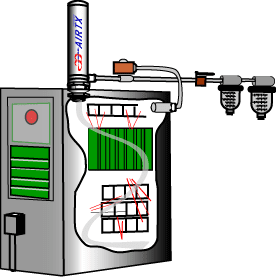

Multiple Face Machining

The large investment in programming for this horizontal/vertical machining center is protected by the Model 70325 Stainless Thermostatic Cabinet Cooler, which eliminates heat build-up and coolant contamination of sensitive electronics.

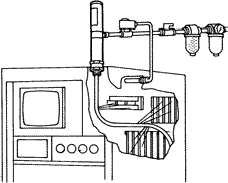

CNC Machining

The Model 70325 Stainless Cabinet Cooling System protects against fluctuations in this precision grinding operation by cooling the cabinet and allowing the electronics to be sealed against mist contamination. Thermostatic control assures you of efficient compressed air usage.

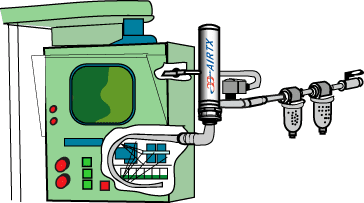

Chemical Processing

The Model 70315 Thermostatic Cabinet Cooling System mounts on the side of this control, out of the operator’s way, allowing free rotation of the control and clear view of the process. Thermostatic control minimizes air usage.

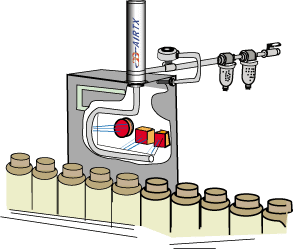

Bottling Plant

AiRTX Cabinet Cooling Systems are stainless steel, so washdown of these leak testing and production controls in a bottling operation is easy. NEMA cabinets can be secured without concern for heat build-up.

AiRTX Polar Cabinet Cooler Advantages

- Higher BTH per CFM

- Greater cooling with the same air usages

- Available in Stainless Steel and Aluminum

- Wide range of Cooling (600-5600 BTUH)

- No vibration to affect CCTV cameras

- Thermostatically controlled units available

- Compact for cramped factory areas

- No maintenance, no moving parts

- Requires no electricity

- No RF/EMI interference

- No fans or filters

- Muffled for quiet operations

- Maintain NEMA 4, NEMA 4x, and NEMA 12 integrity

Uses For Cabinet Coolers

- Nc/CNC Cabinets

- Industrial PCs

- PLCs

- Measuring instruments and recording devices

- Closed-circuit TV cameras

- Motor controls and relays

Technical Data For Cabinet Coolers

Keep Factory-Floor Controls On-Line With Up To 5600 BTUH Of Cabinet Cooling

Dirt, moisture, hazardous or corrosive materials-a bad environment is the Achilles’ heel of industrial electronic systems. And it’s a real hazard when you have to open the cabinet door to prevent heat build-up.

Compressed-Air-Operated Stainless Cabinet Control Coolers For Hazardous Environments

Using a low-cost, reliable Vortex Tube, compressed-air operated AiRTX Polar™ Cabinet Coolers purge and cool electrical/electronic enclosures with filtered air that’s 45° F colder than your compressed air supply. A built-in relief valve lets hot air escape from the cabinet enclosure, while the cooler supplies clean, cold air.

They mount-in minutes-in a standard electrical knockout to maintain your NEMA 4, 4x, or 12 rating. A built-in, heavy duty muffler makes the Cabinet Cooler extremely quiet for use in production areas.

Use Them Anywhere!

If you’re an OEM, you’ll find the fit and finish of our Cabinet Coolers a complement to your own equipment.

Thermostatic systems are highly recommended as they produce a truly maintenance free cooling system. No forgetting to turn it on or off, increasing or decreasing air supply on hot days, consuming compressed air when cooling is not necessary, and no thermal hot and cold changes. A constant 90°F (32°C) to provide the electronics with a long life. For double wide cabinets up to 10’W x 6’H x 2’D or cabinets in extreme hot conditions above 150°F, order Model 70370.

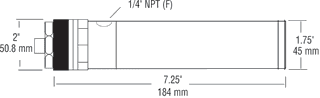

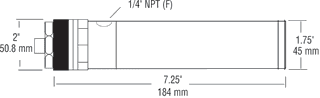

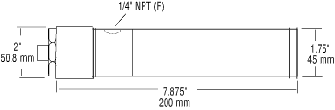

Model 75008, 15, 25, 35 (Aluminum)

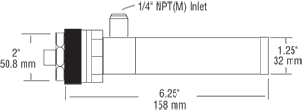

Model 70008 (Stainless Steel)

Model 70015, 25, 35 (Stainless Steel)

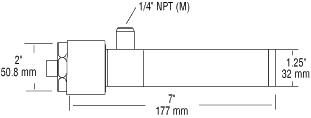

Model 70008X (Stainless Steel)

Model 70015X, 25X, 35X (Stainless Steel)

| NEMA Type 4,12 | NEMA Type 12,4x | NEMA Type 4,12 | |

| Aluminum | Stainless Steel | Stainless Steel | Description |

| 75008 | 70008x | 70008 | 600 BTU/H Cooler and ducting kit, muffler |

| 75108 | 70108x | 70108 | 600 BTU/H Cooler and ducting kit, muffler and 5 micro auto drain filter |

| 75308 | 70308x | 70308 | 600 BTU/H thermostatic system includes: Cooler, auto drain filter, ducting kit, muffler, thermostat, solenoid valve |

| 75105 | 70105x | 70105 | 1100 BTU/H Cooler and ducting kit, muffler |

| 75115 | 70115x | 70115 | 1100 BTU/H Cooler and ducting kit, muffler and 5 micro auto drain filter |

| 75315 | 70315x | 70315 | 1100 BTU/H thermostatic system includes: Cooler, auto drain filter, ducting kit, muffler, thermostat, solenoid valve |

| 75025 | 70025x | 70025 | 1800 BTU/H Cooler and ducting kit, muffler |

| 75125 | 70125x | 70125 | 1800 BTU/H Cooler and ducting kit, muffler and 5 micro auto drain filter |

| 75325 | 70325x | 70325 | 1800 BTU/H thermostatic system includes: Cooler, auto drain filter, ducting kit, muffler, thermostat, solenoid valve |

| 75035 | 70035x | 70035 | 2800 BTU/H Cooler and ducting kit, muffler |

| 75135 | 70135x | 70135 | 2800 BTU/H Cooler and ducting kit, muffler and 5 micro auto drain filter |

| 75335 | 70335x | 70335 | 2800 BTU/H thermostatic system includes: Cooler, auto drain filter, ducting kit, muffler, thermostat, solenoid valve |

| 75370 | 70370x | 70370 | 5600 BTU/H thermostatic system includes: 2 Coolers (model 70035), auto drain filter, ducting kit, muffler, thermostat, solenoid valve |

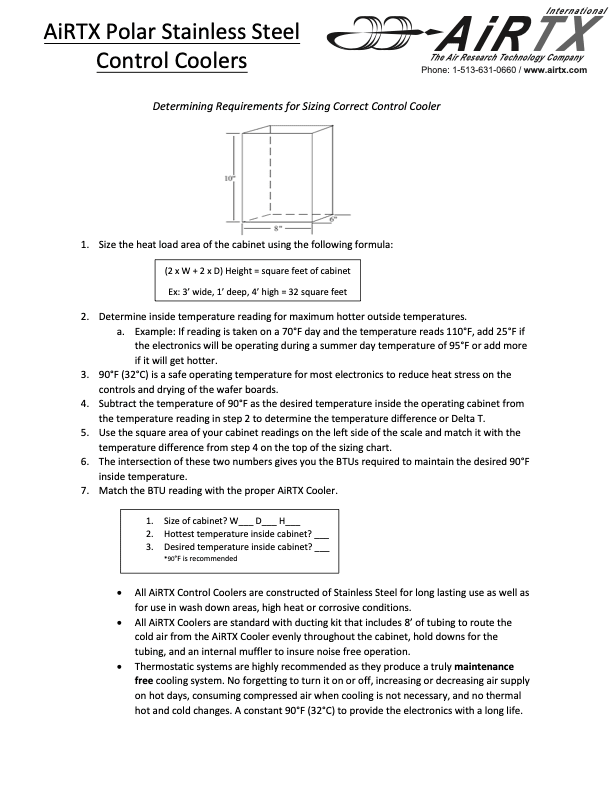

Installation Of Thermostatic Cabinet Control Cooler System

| Double Wide System Components Model 70370: | ||

| 2 of Model | 70035 | Cooler with Conducting Kit |

| 1 of Model | 90302 | Solenoid |

| 1 of Model | 90300 | Adjustable Thermostat |

| 1 of Model | 90176 | Auto Drain Filter |

| NEMA TYPE 4,12 | NEMA TYPE 4,12 | NEMA TYPE 12,4x | Inlet Pressure | Air Consumption | Capacity | |||

| psi | (BAR) | (CFM) | (LPM) | (BTU/N) | (Kcal/H) | |||

| Aluminum | SS | SS | ||||||

| 75008 | 70008 | 70008x | 100 | 7 | 8 | 225 | 600 | 150 |

| 75015 | 70015 | 70015x | 100 | 7 | 15 | 425 | 1100 | 280 |

| 75025 | 70025 | 70025x | 100 | 7 | 25 | 700 | 1800 | 450 |

| 70035 | 70035 | 70035x | 100 | 7 | 35 | 990 | 2800 | 700 |

| 75370 | 70370 | 70370x | 100 | 7 | 70 | 1980 | 5600 | |