More Power at a Fraction of the Cost of Open Copper Tubes or Plastic Nozzles

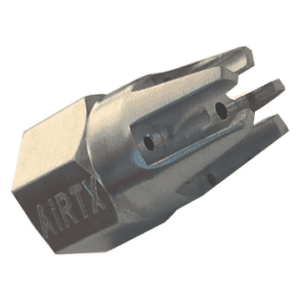

AiRTX Air Nozzles are uniquely designed to drastically reduce compressed air consumption. The Air Nozzles harness the power of compressed air to do big blow-off, cooling, and parts ejection jobs. The AiRTX Air Nozzle does all this without spewing raw compressed air and noise all over your plant.

AiRTX Air Nozzles are uniquely designed to drastically reduce compressed air consumption. The Air Nozzles harness the power of compressed air to do big blow-off, cooling, and parts ejection jobs. The AiRTX Air Nozzle does all this without spewing raw compressed air and noise all over your plant.

They are ideal for anything from a hand-held blow-off gun to multi-unit nozzle manifolds for conveyorized products of transfer lines. Even small air usage applications can show major cost reduction due to energy savings.

AiRTX air nozzles generate high volume and thrust with low air consumption. Air Compressor usage is greatly reduced with AiRTX air nozzles, leading to equipment cost savings. AiRTX air nozzles satisfy OSHA requirements for noise as well as dead end pressure.

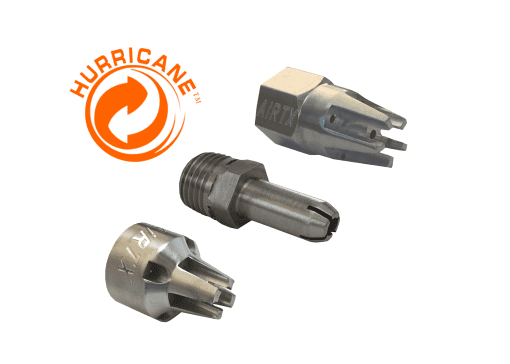

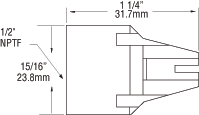

The Hurricane Line of Nozzles provide the benefits of the standard line AiRTX Nozzles but have greater thrust. When power is needed for moving heavy objects, removing large amounts of liquids from parts in a short time, and larger air flows for quicker drying, the Hurricane nozzle is the perfect option.

Contact Your Electric Company!

They may be offering hard cash for buying AiRTX Air Nozzles to save energy. Duke Energy for example, offers up to $20.00 for each AiRTX Air Nozzle that reduces kWh energy use. Call us for details 800-307-7475.

Nozzles Products

-

Single Point Ionizer

$228.00 Add to cart -

Adjustable Air Nozzle

$24.00 – $153.00 Select options This product has multiple variants. The options may be chosen on the product page -

40009CCT Custom Air Nozzle

$55.00 Add to cart -

Blow Gun

$51.00 – $69.00 Select options This product has multiple variants. The options may be chosen on the product page -

Fixed Flow Air Nozzles

$21.00 – $44.00 Select options This product has multiple variants. The options may be chosen on the product page -

Force Nozzles

$40.00 – $126.00 Select options This product has multiple variants. The options may be chosen on the product page

INDUSTRIAL SOLUTIONS FOR NOZZLES

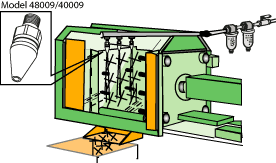

Molding

The Model 48009 Adjustable Air Saver Nozzle uses a minimal amount of compressed air to reduce high volume and cooling for quick part release. Small size and instant on/off make it ideal for molding machines.

Food Industry

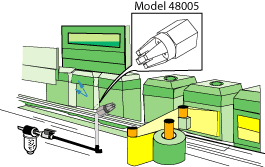

The Fixed Flow Nozzle 48005 is ideal for drying food containers prior to labeling. It will not pit or need replacement in this wet environment. Sta-Put Hose Model 40000 series holds Nozzle Model 48005 in place, replacing copper tube.

Drilling – Chip Removal

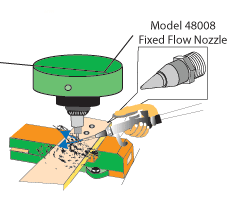

The 25:1 air amplification of the Model 48008 Fixed Flow Air Saver Nozzle provides plenty of cleaning power for a factory air gun, while still meeting OSHA requirements for dead-end pressure and noise limits.

USES FOR AIRTX NOZZLES

- Replacing direct compressed air use – pipe nipples and copper tube

- Ejecting parts from molding machines and stamping presses

- Blow-off of chips, trim scrap, swarf

- Part cleaning before painting

- Plant air conservation and noise reduction

- Cooling molded or cast parts

- Cleaning/cooling of metal strip and plastic/paper webs

- Cleaning/cooling of conveyorized or transfer line parts

- Manifolds available for multiple units

STAINLESS STEEL AIR SAVER NOZZLES ARE IDEAL FOR

- Food processing

- Hot corrosive environments

- Maximum durability in harsh environments

AiRTX Nozzles Advantages

- Cuts energy bill by 50-90%

- Meets OSHA noise and dead-end pressure requirements.

- Increase air flow by 50:1

- Reduce noise level by 50dBA or more.

- Reduce compressed air usage without losing production.

- A variety of adjustable, fixed flow styles and thrusts available.

- Low initial and operating costs

- Mountable on Sta-Put Hoses, Blow Guns, and Manifolds

AIRTX AIR SAVER NOZZLES ADVANTAGES

- Generates high volume with lowest possible air consumption

- Adjustability makes them easy to adapt to existing applications and immediately cut air use to a minimum for the job

- Greatly reduces demand on the compressor

- Low initial and operating costs

- Meets OSHA noise and dead-end pressure requirements

- Easy to control flow/force

- Longer stream of high velocity air

- Adjustable air flow

- Set screw for locking air usage

TECHNICAL DATA FOR NOZZLES

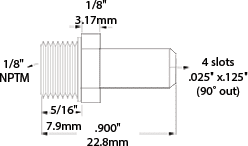

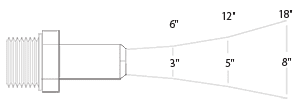

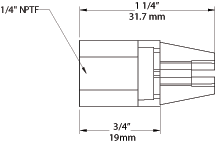

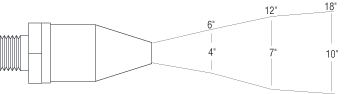

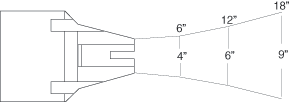

MODEL 48004

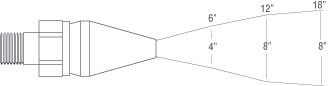

Nozzle Blow-Off Forces in Ounces Of Thrust (Nozzle is preset to consume 15 cfm @ 80 psi)

| Distance from Target | Pressure (PSIG) | |||

| 40 | 60 | 80 | 100 | |

| 6″ | 12 | 16 | 20 | 22 |

| 12″ | 11 | 15 | 18 | 21 |

| 18″ | 10 | 13 | 16 | 18 |

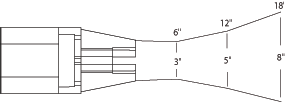

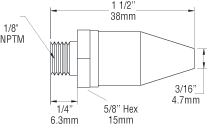

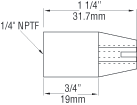

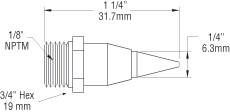

MODEL 48009 (ALUMINUM), MODEL 40009 (STAINLESS STEEL)

Nozzle Blow-Off Forces in Ounces Of Thrust (Air Saver Nozzle is preset to consume 15 cfm @ 80 psi)

| Distance from Target | Pressure (PSIG) | |||

| 40 | 60 | 80 | 100 | |

| 6″ | 7.7 | 12.2 | 16.5 | 20.6 |

| 12″ | 7.6 | 11.5 | 15.9 | 20.1 |

| 18″ | 6.9 | 10.0 | 13.3 | 16.8 |

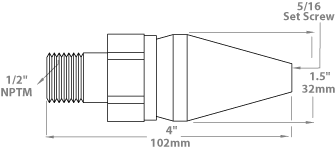

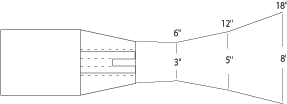

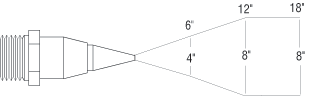

MODEL 48109

Nozzle Blow-Off Forces in Ounces Of Thrust

| Distance from Target | Pressure (PSIG) | |||

| 40 | 60 | 80 | 100 | |

| 6″ | 16 | 24 | 33 | 41 |

| 12″ | 15 | 22 | 27 | 40 |

| 18″ | 14 | 20 | 22 | 34 |

FIXED FLOW NOZZLES

MODEL 48002

Nozzle Blow-Off Forces in Ounces Of Thrust

| Pressure (PSIG) | ||||

| 40 | 60 | 80 | 100 | |

| Air Usage CFM | 0.6 | 1.2 | 1.8 | 2.2 |

MODEL 48005

Nozzle Blow-Off Forces in Ounces Of Thrust

| Distance from Target | Pressure (PSIG) | |||

| 40 | 60 | 80 | 100 | |

| 6″ | 19 | 34 | 44 | 50 |

| 12″ | 17 | 32 | 42 | 48 |

| 18″ | 13 | 27 | 38 | 44 |

| Air Usage CFM | 17 | 24 | 28 | 36 |

MODEL 48006

Nozzle Blow-Off Forces in Ounces Of Thrust

| Distance from Target | Pressure (PSIG) | |||

| 40 | 60 | 80 | 100 | |

| 6″ | 4.5 | 6.1 | 8 | 11.6 |

| 12″ | 4 | 5.7 | 8.3 | 11 |

| 18″ | 3.7 | 5.2 | 7.5 | 10.8 |

| Air Usage CFM | 6 | 7 | 9 | 11 |

MODEL 48007

Nozzle Blow-Off Forces in Ounces Of Thrust

| Distance from Target | Pressure (PSIG) | |||

| 40 | 60 | 80 | 100 | |

| 6″ | 9 | 16 | 21 | 24 |

| 12″ | 8 | 15 | 20 | 23 |

| 18″ | 6 | 13 | 18 | 21 |

| Air Usage CFM | 9 | 13 | 15 | 19 |

MODEL 48107

Nozzle Blow-Off Forces in Ounces Of Thrust

| Distance from Target | Pressure (PSIG) | |||

| 40 | 60 | 80 | 100 | |

| 6″ | 16 | 24 | 34 | 46 |

| 12″ | 14 | 25 | 32 | 40 |

| 18″ | 12 | 20 | 28 | 38 |

| Air Usage CFM | 23 | 28 | 32 | 35 |

MODEL 48008, 40008, 48010

Nozzle Blow-Off Forces in Ounces Of Thrust

| Distance from Target | Pressure (PSIG) | |||

| 40 | 60 | 80 | 100 | |

| 6″ | 4.5 | 6.1 | 8.0 | 11.6 |

| 12″ | 4.0 | 5.7 | 8.3 | 11 |

| 18″ | 3.7 | 5.2 | 7.5 | 10.8 |

| Air Usage CFM | 6.0 | 7.0 | 9.0 | 11 |