Instantly Control Air Temperature

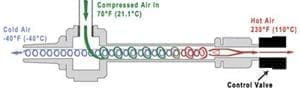

Instant cold or hot air – from -40°f to 230°f – from ordinary compressed air.

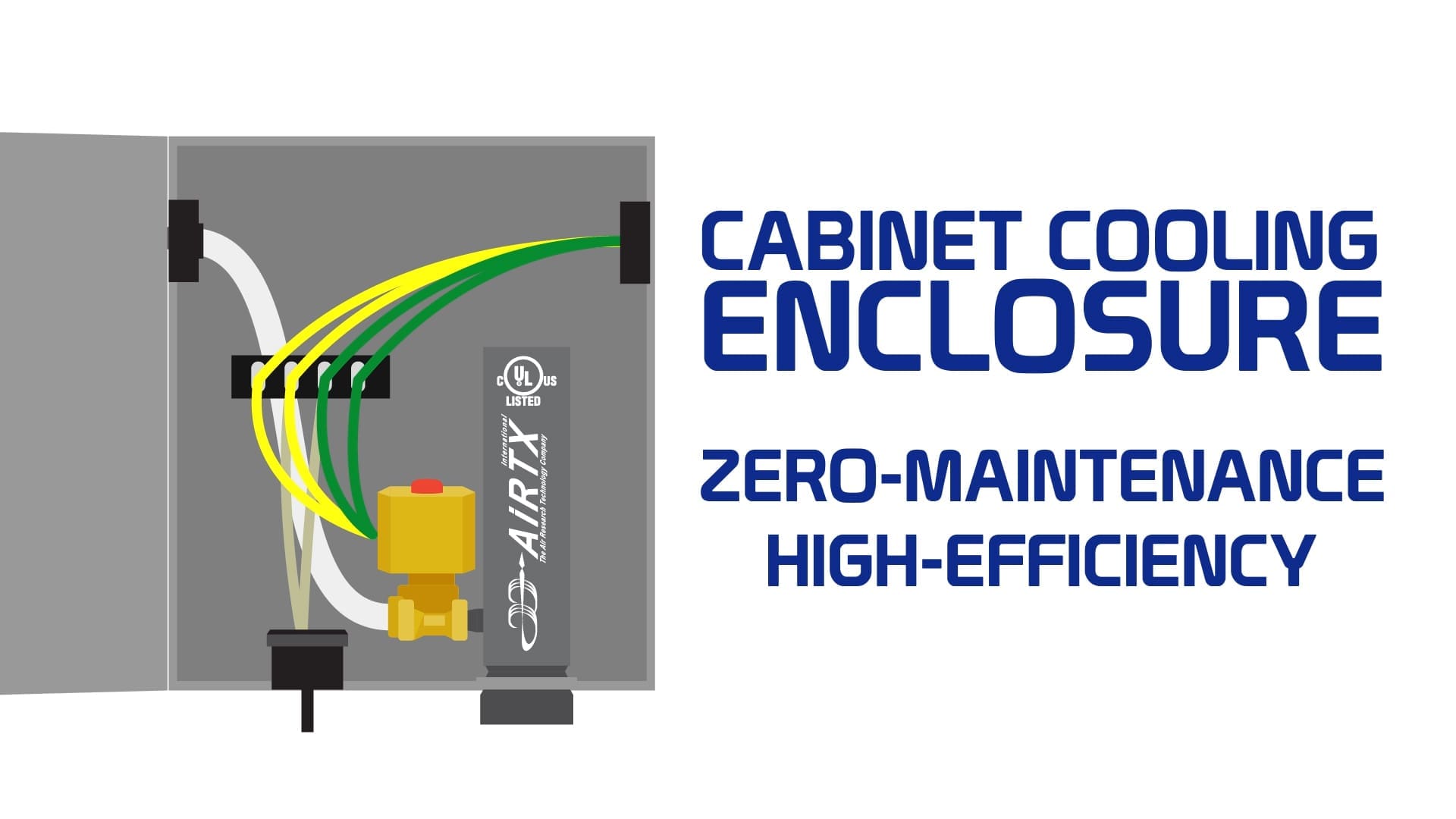

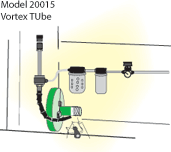

It’s your answer for instant cold air, where and when you need it, using nothing but compressed air as a power source. There’s no maintenance, no mess, no explosion hazard, no electricity, no moving parts – just clean, cold air for industrial or laboratory spot cooling.

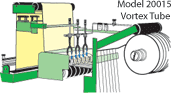

Vortex Tubes from AiRTX – Precision Stainless Steel for the Price of the “Other Guys” Aluminum Tubes

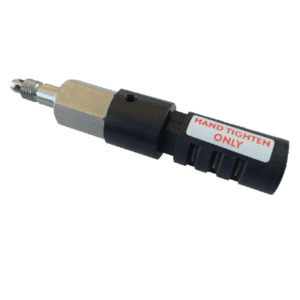

Starting with corrosion-resistant, food-grade Stainless Steel as the principal material of construction, AiRTX designers have optimized every aspect of Vortex Tube design for convenience, dependable performance, and long-lasting service.

The AiRTX Vortex Tube is as good-looking as it is functional. It’s precision-machined, assembled, and tested.

Manufactured to exacting tolerances, AiRTX Vortex Tubes are produced under strict quality control to ensure years of reliable, maintenance-free operation.

*inlet temperature 70°F/21.1°C

Vortex Tubes Products

-

Vortex Tubes

$191.00 – $510.00 Select options This product has multiple variants. The options may be chosen on the product page -

Vortex Tube Accessories

$19.00 – $119.00 Select options This product has multiple variants. The options may be chosen on the product page -

Application Development Kit

$457.00 Select options This product has multiple variants. The options may be chosen on the product page -

Cold End Muffler

$67.00 Add to cart -

Cold End Muffler for Model 20008

$58.00 Add to cart -

Hot End Muffler

$29.00 Add to cart -

Hot End Muffler for Model 20008

$48.00 Add to cart

Industrial Solutions For Vortex Tubes

Metal Fabricating – Tapping

Tapping brass clips is completed without messy liquid coolants using air from a Vortex Tube to cool the tap. The brass does not have a chance to gum up, the cut is cleaner, and secondary operations are eliminated.

Plastic – Slitting

Cutting wheels on this slitter can work at top speed and stay sharper longer – when cold air from Vortex Tubes eliminates the friction heat build-up. The trim edge is also cleaner.

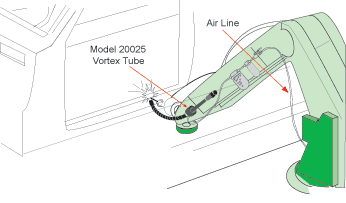

Transportation Spot-Welding

Cooling this spot-welding operation with a Vortex Tube virtually eliminates secondary smoothing operations, and greatly improves the appearance of the product.

Metalworking – Single Point Threading

Heat build-up in this single point threading operation can shorten tool life and produce a rough thread. Clean, dry, sub-zero cooling allows increased speed, while eliminating tool microcracking and premature failure.