The AiRTX Hurricane Adjustable Air Amplifier is used for quiet, safe, efficient ventilation, air conveying and blow off without electricity or moving parts.

The AiRTX Hurricane Adjustable Air Amplifier is used for quiet, safe, efficient ventilation, air conveying and blow off without electricity or moving parts.

AiRTX Hurricane Adjustable Air Amplifiers can handle big air jobs with just a small amount of compressed air. Similar to a vacuum, they can be used ducted or open to handle dusts, fumes or granular, stringy material. Output is fully adjustable without tools or air-wasting shims, making set-up a breeze. 5 sizes available in Aluminum and 4 sizes in Stainless Steel.

In ducted applications, Air Amplifiers deliver amplification ratios of 12-25:1, capable of producing output flows of 100 to 2000 SCFM (2800-56,000 SLPM), using the factory-set nozzle opening (which you can change). Un-ducted amplification ratios range from 36-75:1.

Use Model 15008R and Model 15015R on the suction end for in-line conveying applications.

Hurricane Air Amplifiers Products

-

HURRICANE Adjustable Air Amplifier

$81.00 – $1,519.00 Select options This product has multiple variants. The options may be chosen on the product page

INDUSTRIAL SOLUTIONS FOR AIR AMPLIFIERS

METALWORKING – GRINDING

A model 15015 Ai r Amplifier boosts a vacuum system by 300 SCFM, negating the need for a larger, more expensive system to remove grinding dust.

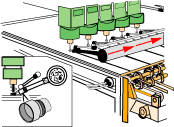

WOODWORKING – SAWDUST REMOVAL

Model 15008 Amplifier boosts the vacuum system, ending a sawdust problem on this router. Compressed-air-operated, with no moving parts, the amplifier eliminates frequent electric motor replacement.

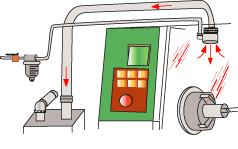

COOLANT MIST REMOVAL

Even with doors closed, oily mist often escapes to surrounding areas. The model 15008 Air Amplifier solves the problem, without failure of electric motors or expensive vacuum systems.

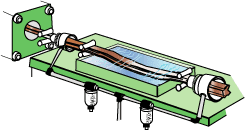

EXTRUSION – RUBBER MOLDING COOLING/DRYING

Model 10015 Stainless Steel Amplifiers help set-up and cool this molding after extrusion. Then, they blow off and dry the molding prior to cutting.

USES FOR AIRTX AIR AMPLIFIERS

- Air conveying any material that can be moved in a rush of air: chips, sawdust, smoke, paper and cloth trim, grain, dust, capsules, powder

- Ventilation and exhaust of smoke/fumes, replacing fans

- Blow-off chips, trim scrap, water, dust

- Part cleaning before finishing, replacing open air lines

- Purging tanks

- Cooling molded parts and cast-ings

- Cleaning/cooling of conveyed parts

- Pneumatic conveying

AiRTX Air Amplifier Advantages

- Low cost

- Greatly reduced noise

- Easy to control flow/force

- Adjustable output without tools or shims

- No blades, guards or clumsy duct

- No maintenance, no moving parts

- No electricity or explosion hazard

- Instant on/off

- Available in Stainless and Aluminum

The AiRTX Hurricane Adjustable Air Amplifier is used for quiet, safe and efficient ventilation, air conveying and blow off without electricity or moving parts.

AiRTX Hurricane Adjustable Air Amplifiers do big air handling jobs with just a small amount of compressed air. Use them ducted or open, the same way you’d use a vacuum system, fan, or blower, to handle dusts, fumes or granular, stringy material. Output is fully adjustable without tools or air-wasting shims, making set-up a breeze. 5 sizes available in Aluminum and 4 sizes in Stainless Steel.

In ducted applications, Air Amplifiers deliver amplification ratios of 12-25:1, capable of producing output flows of 100 to 2000 SCFM (2800-56,000 SLPM), using the factory-set nozzle opening (which you can change). Unducted amplification ratios range from 36-75:1.

Use Model 15008R and Model 15015R on the suction end for in-line conveying applications.

TECHNICAL DATA FOR AIR AMPLIFIERS

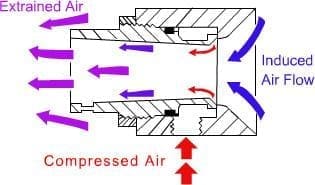

The AiRTX Hurricane Adjustable Air Amplifiers release tiny amounts of compressed air at near-sonic velocity through an adjustable, internal, ring-shaped nozzle. The high-speed “tube” of amplified air released through the front creates a strong vacuum behind itself, pulling additional surrounding air through the rear of the air amplifier, while pushing the ambient air in front.

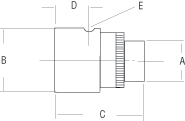

| Air Amplifier Dimensions | ||||||

| Model | A | B | C | D | E | Dia. |

| 15004 | 0.50″ | 1.25″ | 2.175″ | .560″ | 1/8″ NPT | .38″ |

| 10004 | 13mm | 31mm | 56mm | 14mm | 9mm | |

| 15008 | 1.250″ | 2.00″ | 2.625″ | 1.02″ | 1/4″ NPT | 0.80″ |

| 10008 | 31mm | 50mm | 67mm | 26mm | 20mm | |

| 15015 | 2.00″ | 3.00″ | 3.25″ | 1.06″ | 3/8″ NPT | 1.65″ |

| 10015 | 50mm | 76mm | 83mm | 27mm | 41mm | |

| 15025 | 2.5″ | 3.7″ | 3.7″ | 1.2″ | 3/8″ NPT | 2.25″ |

| 10025 | 63mm | 93mm | 93mm | 30mm | 57mm | |

| 15030 | 4.00″ | 5.00″ | 5.00″ | 1.50″ | 1/2″ NPT | 3.00″ |

| 101mm | 127mm | 127mm | 38mm | 76mm | ||

| Air Amplifier Flow Specs at Factory (Adjustable) Setting | ||||

| SS Model# | Aluminum Model # | Throat Diameter | AMP Ratio | Adj. Factory Setting |

| 10004 | 15004 | 0.38″ | 12.1 | 15 cfm |

| 10008 | 15008 | 0.8″ | 12.1 | 15 cfm |

| 10015 | 15015 | 1.5″ | 20.1 | 25 cfm |

| 10025 | 15025 | 2.5″ | 25.1 | 45 cfm |

| 10030 | 15030 | 3 | 30.1 | 60 cfm |

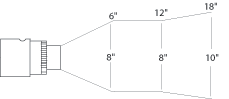

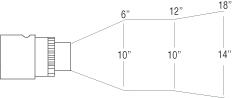

AIR AMPLIFIER MODEL 15008, 15015 FLOW PATTERN

AIR AMPLIFIER MODEL 15025, 15030 FLOW PATTERN