Powerful Blow-Off with Lower Air Cost and Lower Noise than straight Compressed Air Tubes

The High Thrust Jet is not only a variable nozzle for blow-off and drying applications, but an industrial strength in-line vacuum for conveying dust, powders, and small parts.

Don’t buy another compressor …changeover to AiRTX ™ Jets…cut noise and energy too!

Heavy blow-off and air conveying jobs can overwork your compressor and shorten the time between expensive overhauls. A 1/4″ (6mm) air tube uses the entire output of a 10-hp compressor, sending energy costs out of sight, hitting 100 dBA noise levels, and violating OSHA dead-end air pressure limits. Air Saver Jets give you an edge with air amplification. Safer and quieter, they amplify compressed air flow four times, delivering high thrust with a fraction of the air used by open air lines. Plant-wide changeover to AiRTX Jets is like adding compressor capacity. They’ll:

- Cut your energy bill

- Increase air flow with lower noise level

- Reduce demand on your compressor

- Give you a return on investment in weeks, if not days

Need Extended Reach? Customize your nozzle with: Sta-Put Hoses, Blow Guns & Manifolds.

Adjustable Air Jets Products

-

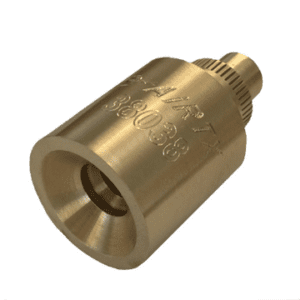

38038R High Thrust Adjustable Air Jet

$83.00 Add to cart -

Adjustable Air Jets

Price range: $85.00 through $90.00 Select options This product has multiple variants. The options may be chosen on the product page

Industrial Solutions For High Thrust Jets

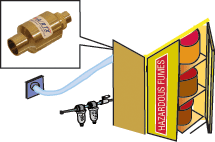

Fume Removal

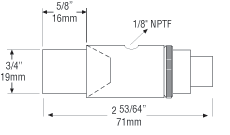

A low cost, maintenance free AiRTX Jet system uses only 3 cfm (85 lpm) of compressed air to remove hazardous fumes from this solvent storage cabinet, The air flow amplification of High Thrust Jet Model 38044 provides the needed ventilation without dangerous fan blades or expensive electric motors.

Metalworking

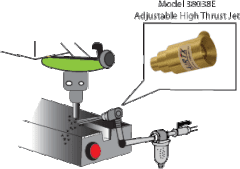

This milling operation is enhanced by the chip removal and cooling provided by the Model 38038E Adjustable High Thrust Jet. The Adjustable Jet provides plenty of thrust to prevent build-up of metal chips and coolant around the tool.

AiRTX High Thrust Jets Advantages

- Low initial and operating costs

- Meet OSHA noise and dead-end pressure requirements

- Easy to control flow/force

- Instant on/off, no vibration

- No maintenance, no moving parts

- No electricity or explosion hazard

- No RF/EMI interference

- Adjustable flow/force

- Solid brass construction

- Model 38038 dead-ended suction @80 psi, 18 cfm is 189″ water column

Uses For AiRTX High Thrust Jets

- Ejecting parts from molding machines and stamping presses

- Blow-off of chips, trim scrap and swarf

- Air conveying dusts, powders and fibers

- Part cleaning before painting

- Cooling extruded parts

- Cleaning/cooling of metal strip and plastic/paper webs

- Cleaning/cooling of conveyors and conveyorized parts

The Hurricane Line of Nozzles provide the benefits of the AiRTX Nozzles but have greater thrust when power is needed for moving heavy objects, removing large amounts of liquids from parts in a short time, and larger air flows for quicker drying.

Technical Data For High Thrust Jets

Air Saver High-Thrust Jets release a tiny amount of compressed air at near-sonic velocity through a fine, internal, ring-shaped nozzle. The high-speed “tube” of air ejected through the front creates a strong vacuum behind itself, pulling additional surrounding air through the rear of the jet, while pushing the ambient air in front.

Don’t Buy Another Compressor… Changeover To AiRTX™ Jets… Cut Noise and Energy Too!

Heavy blow-off and air conveying jobs can overwork your compressor and shorten the time between expensive overhauls. A 1/4″ (6mm) air tube uses the entire output of a 10-hp compressor, sending energy costs out of sight, hitting 100 dBA noise levels, and violating OSHA dead-end air pressure limits. Air Saver Jets give you an edge with air amplification. Safer and quieter, they amplify compressed air flow four times, delivering high thrust with a fraction of the air used by open air lines. Plant-wide changeover to AiRTX Jets is like adding compressor capacity. They’ll:

- Cut your energy bill

- Increase air flow with lower noise level

- Reduce demand on your compressor

- Give you a return on investment in weeks, if not days.

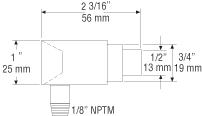

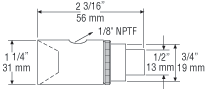

Three Models: Adjustable Unit For Easy Set-Up, with Air Conveying Capability

Our Adjustable High-Thrust Jet simplifies set-up or system change because you can alter the flow and thrust with a quick twist of the nozzle. Just install it on your air line and set it to do the job. The In-Line Air Jet is ideal for retrofitting open air line blowoff applications where system set-up does not change frequently. It can also air convey fine granular product, with a 3/4″ (19mm) diameter inlet for attachment of tubing. It develops 54″ W.C. suction and 5.6 oz. (150 gm) thrust with 80 PSIG (5 BAR) air.

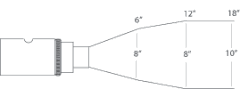

| Jet Blow-Off Force in Ounces of Thrust | ||||

| Distance from Target | Pressure (PSIG) | |||

| 40psi | 60psi | 80psi | 100psi | |

| 6″ | 7.5 | 11.8 | 16.5 | 22.2 |

| 12″ | 6.9 | 11.5 | 16.2 | 21.4 |

| 18″ | 5.6 | 9.3 | 13.7 | 17.4 |

Model 38038E

Model 38038

Model 38044

Flowpattern